Autonomous Gas Power Station - Additional information

Design of gas (gas-piston) units (GPU)

A gas-piston engine, which is an ICE with external mixture formation and a spark ignition of the combustible mixture in the combustion chamber, is used as a power unit in GPU. In the gas engine, the energy released by combustion of fuel produces mechanical work on a shaft that is used to generate electricity by electric current generator. Gas engines are used to operate in generator sets intended for constant and periodic operation (peak loads) with combined generation of electricity and heat (mini-TPP), as well as emergency power sources.

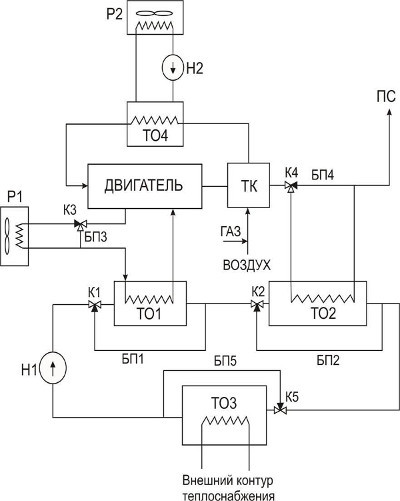

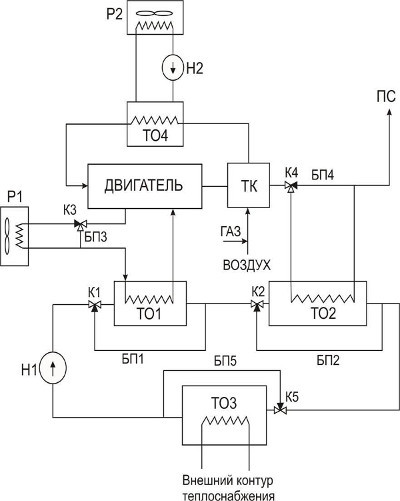

Р – radiator, ДВИГАТЕЛЬ – engine, ГАЗ - gas, Н – pump, ТК – three-way valve, ВОЗДУХ - air, ПС – combustion products, К – cock, Внешний контур теплоснабжения - External heat supply circuit, ТО – heat exchanger, БП – bypass.

With heat recovery (installation of heat exchangers for heating the coolant by combustion products and engine cooling system), it is possible to achieve an increase in efficiency (fuel efficiency ratio). The amount of heat produced at the mini-CHP directly depends on electrical load of the complex and is approximately 1.2-1.3 of the electrical load for foreign engines (with a higher mechanical efficiency) and 1.3-1.5 for domestic engines. The overall efficiency is approximately the same and amounts to 81-85%. The heat exchange unit consists of a plate heat exchanger to recover heat of the cooling liquid (water, glycol), heat exchangers, utilizing heat of the combustion products, engine radiator, fan with the electric drive cooled by the air flow, bypasses system, control valves, sensors and stop valves.

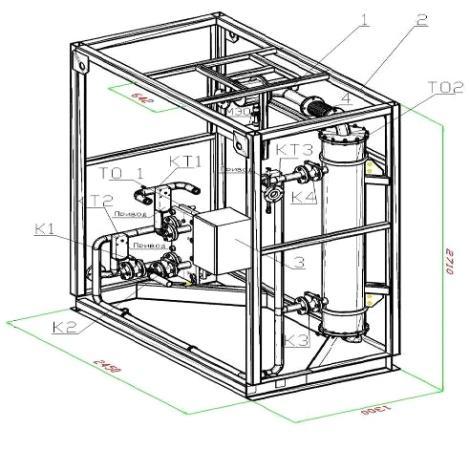

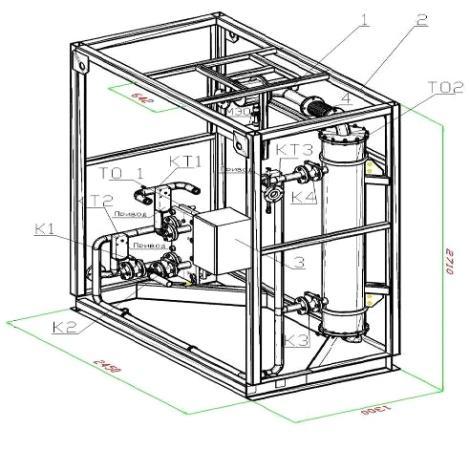

Т01- plate heat exchanger, Т02 – shell-tube heat exchanger, КТ1...КТ3 – three-way control valve with actuator, К1....К4 – ball cock, 1 – bypass valve, 2 – recovery unit frame, 3 - remote control, МЭО – single-turn electric mechanism, 4 – thermal compensator, Привод - Drive

The heat recovery unit designed for 100 kW gas-piston installation

Reference Information

- Production of gas installations is being carried out for more than 8 years.

- The products are certified and approved for use.

- Installations with a capacity of 30-315 kW are being operated throughout the whole territory of the RF - from Sakhalin to the European part.

- On natural gas: Kurgan, mini-CHP 200 kW, Yakutia, 60 and 315 kW, Orenburg, Stavropol, Caucasus, European part of the RF – from 30 to 315 kW;

- On associated gas: Tomsk reg. (operation completed), KamchatkGazprom (100 kW, in operation), YuzhUralNefteGas (315 kW 6 PCs, in operation)

- Preliminary tests of work on generator (pyrolysis) gas (processing of sawdust, peat, etc.) conducted

- The cost of generating 1 kWh of electric power by autonomous mini-CHPs on natural gas and products of thermal processing of local fuels (peat, wood waste, certain types of agricultural waste) is 0.9 - 2 rubles. Payback costs 3-5 years.

- The cost price of electricity on associated gas is only the cost of maintenance. The payback period for installation costs was 1 month.

The most demanded power range is from 100 kW to 1 MW.